![]()

|

FireDot.com |

![]()

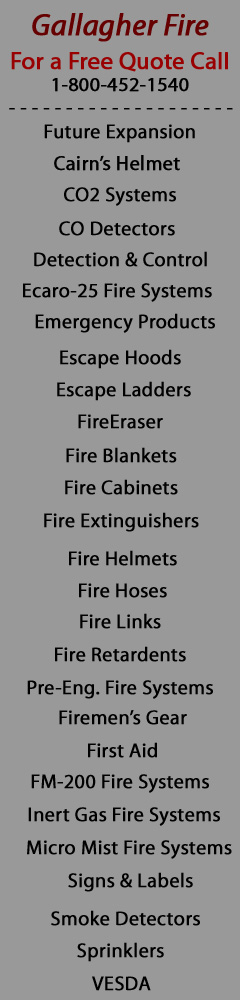

Range

Guard

Wet Chemical System

Fire Suppression System for Commercial Cooking Applications

|

Guarding

Against...

|

Each Range Guard® system comes with:

Over 37 Years of Proven Performance Range Guard was the first UL-listed wet chemical fire suppression system

Built-In Cost Savings

Range Guard’s pre-engineered design gives you: optimal versatility, safety,

and effectiveness inexpensive hardware and system installation fast and

cost-effective system maintenance & upgrades

World Class Service

Badger Fire Protection backs all its products with the best customer service and

technical support. Range Guard comes with Badger’s assurance of the highest

quality workmanship and service.

First with the Best!

- Range Guard®, Badger Fire Protection’s Wet Chemical Fire Suppression System, uses KARBALOY, the superior wet chemical agent first developed over 37 years ago. Range Guard was the FIRST, and remains the BEST!

- Range Guard systems guard

against

- facility damage

- potential injury of personnel and patrons

- lost profits due to business interruption

- Range Guard systems assure

- quick fire detection and suppression

- 24-hour, continual fire protection

- superior wet chemical coverage that quickly

- suppresses fires and prevents reflash

- quick clean up

- Range Guard exceeds UL 300 standards

...could mean everything to the

success of your business!

Rely on Range Guard for:

- rapid fire detection with state-of-the-art heat detectors

- removal of heat source as Range Guard system automatically turns off appliances

- immediate fire suppression as wet chemical agent is sprayed on hazard area with special nozzles designed to give optimal coverage; wet agent provides superior saponification, which quickly snuffs flames and prevents reflash

- quick, easy clean up once appliances have cooled, the agent can be easily wiped away from equipment

Easy and

Affordable to Install & Maintain

- Range Guard systems offer maximum protection with minimum maintenance

- Range Guard’s pre-engineered systems are more cost effective because flexible, versatile system components save on hardware and installation costs

- Range Guard system recharging is fast and economical; great for keeping maintenance costs low

- Range Guard’s nozzles can be placed outside the appliance perimeter for ease of installation

More Choice

- Range Guard

gives you optimal control; lots of choices

fire suppression using automatic and/or manual operation modes - Custom fit

Range Guard systems are designed to easily fit in any kitchen layout - System

updates use existing hardware

Range Guard strives to utilize existing system components to implement updates and improvements, making innovations and upgrades more cost effective

click for large view

Range Guard provides...

- total hazard coverage

- automatic fuel shutdown

- fast flame knockout

- cooling and smothering

- prevention of reflash

- automatic alarm signal

- Listed by Underwriters Laboratories, Inc., tested to UL 300

- Listed by Underwriters Laboratories of Canada, tested to ULC/ORD-1254C.6

- Conforms to NFPA standards 17A and 96

- New York City MEA approval

- DOT rated steel cylinders

Certified

Quality

Certified

Quality

Badger's Range Guard Wet Chemical Fire Suppression System is made in America in accordance with ISO 9001 certified quality standards.

Features of the System

- Designed to address the total fire hazard

- Flexible piping configurations

- Choice of black, chrome plated and stainless steel piping or stainless steel and brass tubing

- Operating and storage temperature 0°F (-18°C) to 120°F (49°C)

- Factory filled stored pressure cylinders with chrome plated valves

- Valves incorporate pressure gauges for at a glance readiness status

- Cylinders can be piped together to minimize installation cost

- Six temperature heat detectors available for precise hazard specification

- Easily identifiable smaller nozzles with integral strainers and foil bursting discs to protect against blockage during discharge

- Swivel adaptors available for nozzles

- Optional stainless steel enclosure